Engine Builds for Dummies...Part 4

_________________________

_________________________

Sup guys. So last time you read this you saw that I had finally gotten to the bottom end of this big assortment of Lego blocks that Honda guys like to call an engine! Well, today we're going to look at the removal of the cylinder head and the girdle so that we can get a look at the condition of the block, crank, and cylinder walls. The condition of the head is not important because it is not a true VTEC head.

There are ways to get the CRV head to work with VTEC killer cams and have only two roller-rockers work actively on a set of cams, but I prefer not to go this route since I want to daily drive this thing. The pistons are also not important because they are only 9.6:1 in compression and they are also cast, not forged, from the factory. I am doing an all motor setup, so my goals are to have small piston to wall clearances with high compression.

To accomplish this I am currently considering a 2618 alloy piston in 88 mm bore with somewhere from 11.0:1 compression to 12.5:1 compression depending on what tuner I go to.

Anyway, enough of the mumbo jumbo. Let's start unbolting things, shall we?

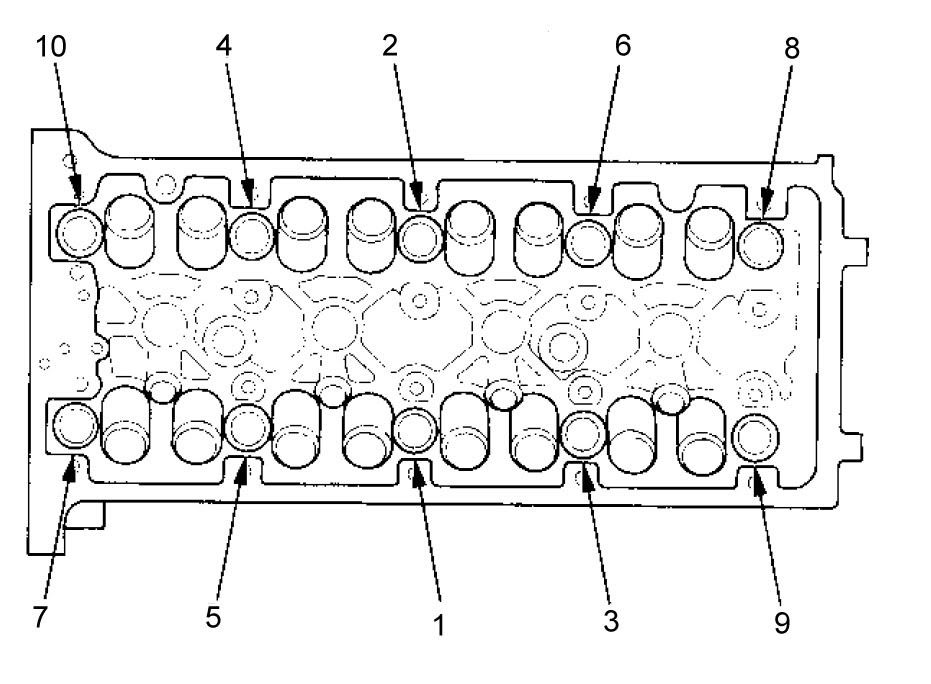

The sequence for unbolting the K24A1 head from the block is as follows:

After doing so, once more loosen them by 1/3 of a full rotation. This isn't absolutely necessary, but I wanted to ensure that I was completely preventing any warpage of the cylinder head.

After loosening the bolts on the cylinder head, take the cylinder head off of the block. I just pulled mine and it came off. You shouldn't need any force to remove this. Here are some shots of the pistons once I removed the head:

Looking at all of the pistons, nothing looked unusual. No pitting in the tops of the pistons leading one to believe that detonation was occurring. The valve reliefs looked uniform on each piston dome, so looks like no piston to valve contact. We will also check that out when we look at the underside of the head. Keep in mind though that it really doesn't matter as I am not reusing these pistons or this head.

However, this all gives me a pretty good idea about the condition of the motor.

After looking at the cylinders, I flipped the head over and checked out the domes and the valves. These looked really good. Better than the head that I have waiting to go on this motor ;)

Taking the engine and flipping it over I started loosening the bolts on the outer part of the girdle in the following order:

You'll find some of these bolts here:

After removing those bolts, I wanted to remove the main bolts on the girdle.

So, that's what I did.

For the sake of being organized, I numbered the main bolts with a pink paint marker and then drew a diagram on a sandwich bag which I then stored them in.

Take out your main bolts, grab yourself a dead-blow hammer, and lightly tap at the sides of the girdle on all sides of the engine until it loosens from the dowel pins on the block.

Here are the crank journals in the girdle. The bearings looked in REALLY good condition when I pulled this whole thing apart. Definitely made me happy to see that nothing was seriously wrong here.

After taking off the girdle, I really started to see the true condition of the motor. You'll see what I mean soon. Check out these pictures of the crank journals. They looked immaculate!

Since I didn't have a 10 mm 12-point socket for a ratchet, I used regular box wrench to take the con-rods off of the crank. Let's take a look at the process, shall we? It's rather simple.

First I loosened both sides of the con-rod:

And then I labeled the bolts and the con-rod bottom halves according to their location in the engine, then removed them.

Here's the top half of the con-rod. It's still sitting on the con-rod journal. Look how good this journal looks. The crank is very shiny, there's no pitting or scouring that I can see. Many of these journals looked exactly like this. I was also very excited to see this!

For this part, some take the wooden end of a hammer and tap the top end of the con-rod out by making contact with the bottom of the piston. I forget what others use...I just used my hands.

And here's the piston removed from the engine.

That's about it for this installment of "Engine Builds for Dummies!"

In the next installment I'll go over inspecting the block with some blueprinting tools and the results that I find :). Thanks for kicking it with me guys.

Until next time....Lexi.Laron...out...

No comments:

Post a Comment

Comment