Welcome one, welcome all, back to another edition of "Engine Building for Dummies!" If you missed any of my previous articles on Project DC5, go ahead and click the links below:

You know, it's tough-- being away from home. It's humbling.

Being alone allows for time to realize one's faults. Without family or friends as close as the ones back home to confide in it is possible for one to gain some serious insight into one's self.

Being alone allows for time to realize one's faults. Without family or friends as close as the ones back home to confide in it is possible for one to gain some serious insight into one's self.

You begin to see your faults, you begin to see your negative thoughts, you begin to see how all of those things affect you.

In a way, being away from home makes you more self-aware, in my opinion. That's one of the things I've learned while out here-- that when you're alone, you have more time for introspection. You have more time to think. Sometimes it's good, but for the most part it's been pretty bad for me lately. I miss my family.

Me by Lake Michigan in Chicago

However, I always remind myself of the positive outcomes of this event in my life. For example, I am much more technically skilled now, especially in my career of chemical engineering.

For the most part, I have become an avid forum reader. I frequent K20A.org every day to learn more about the K motor and what it is capable of, how to build one, what parts to use, what precautions to take, who to trust, who to talk to. The journey of this motor build so far has been a journey in itself.

And I have learned so much more than all of these things. I have learned how to gracefully handle myself around those more intelligent and wise than myself. I have learned to shut my mouth when I need to and how to speak when I have to. I have reaffirmed my belief that listening is more important than anything. Because without listening, you can't learn.

This engine build somewhat embodies all of these learnings. And so I am glad that I can share it with you, my readers on this blog...

Over the weekend, I had a lot of fun. On Saturday night I went ice skating for the first time in a while. I missed ice skating. It reminded me of the days that I used to play ice hockey; doing cross-overs while turning, skating backwards like I was in the crease again, playing goalie, zooming down the ice like I was rushing to the bench or as if I were on a breakaway. It made me wonder if I want to get back into hockey some day. Maybe some day.

I also went snowboarding with my roommate.

We went to Cascade Mountain in Wisconsin, an attraction rated four stars on Google. Although the slopes were a bit icy, we both shredded mad hard, tearing up the green circles, then the blue squares, and eventually the black diamonds. This was my first time on the black diamond! It was also my first time catching air off of a couple of jumps while snowboarding. I couldn't have had more fun!

However now it's back to the work week and back to more engine building. And I really can't complain about either. My job is dope and this engine has been going slowly and smoothly. I guess I just get down sometimes and I can't really help it.

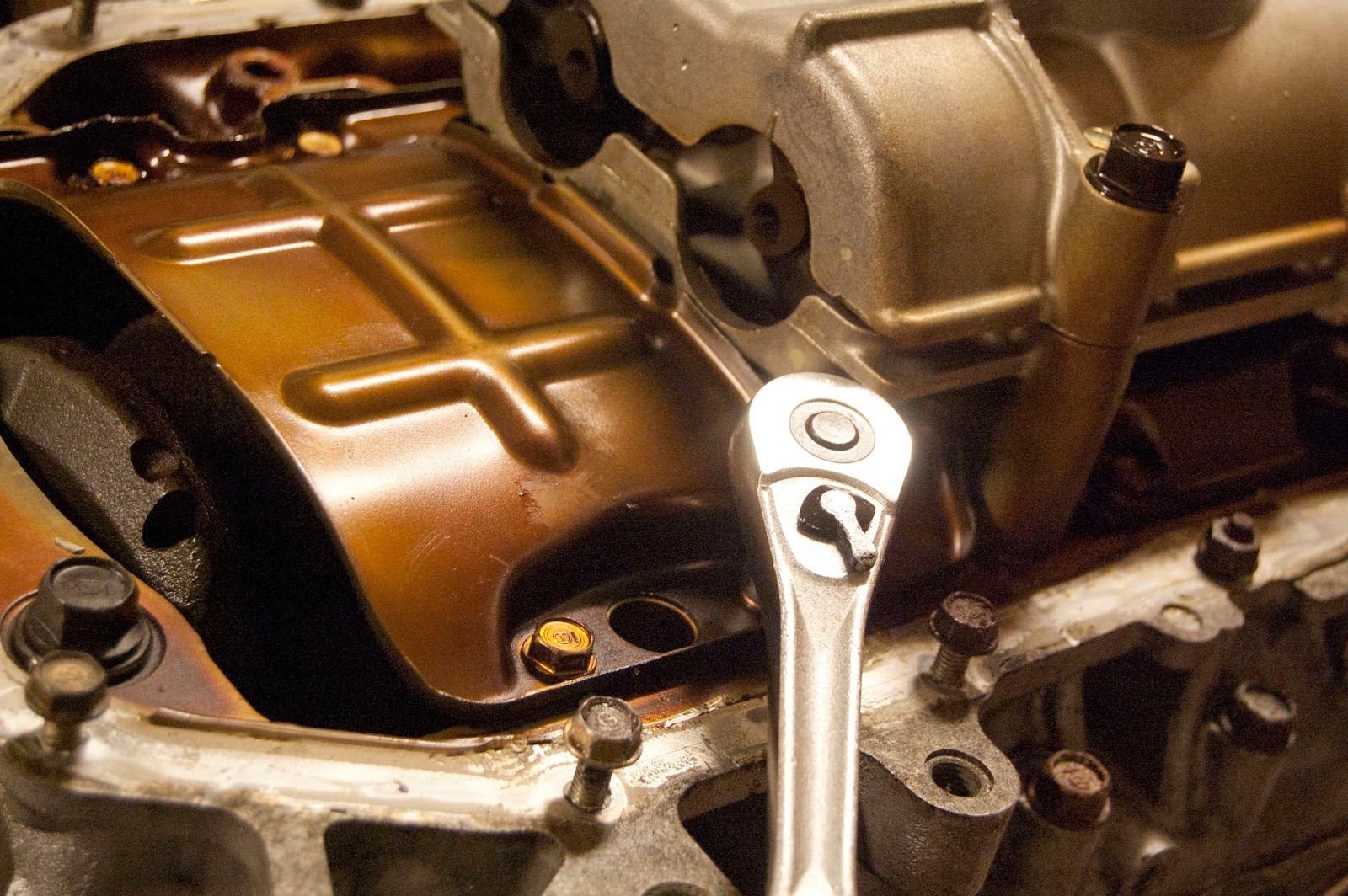

If you remember in my last edition of "Engine Builds for Dummies" I finished removing the timing chain cover, and the tensioners along with the oil pan.

Well, here's the bottom end uncovered! On top of the girdle sits some half baffles, or abbreviated windage trays that prevent oil from getting picked up into the rotating assembly, and a bulky K24A1 oil pump with heavy balance shafts included.

In theory, if the engine did experience some damage which made some metal shavings appear, then they would have appeared in the oil pan. They would have also been apparent in the oil when I drained it. However since there was little to no oil to drain from this motor, I figured another good place to check for large debris of any sort would be in the mesh inside of the oil pickup on the pump.

Let's take a look at the clean pickup's mesh:

Next I removed the abbreviated windage tray.

Finally, after removing the top four bolts on the back half of the abbreviated windage tray, you will see your first piece of crankshaft counterweight! What a beauty!!! Hahah

After I took off the half baffle, I began my work on the oil pump. For starters, you're going to want to remove your tensioner.

I plan on switching to a K20A2 oil pump which has no balance shafts. This will provide less rotating mass which will allow me to rev higher than on a K24A1 oil pump without cavitating the pump. A couple of things are needed for this upgrade, including:

- A 64-link Acura RSX Type-S oil pump chain (PN: 13441-PCX-004)

- An RSX Type-S oil pump chain guide (PN: 13460-PNC-004)

- A sealing bolt and washer to plug a hole in the girdle which would have supplied the K24A1 oil pump's balance shaft assembly if it were still bolted to the engine (PN: 90004-PE2-005 and 90401-PE2-003)

- Bolts for the oil pump (PN: 95701-06025-08 and 95701-08050-08 and 95701-08075-08)

- And the pump itself, of course (PN: 15100-PRB-A01)

Notice that the K20A2 tensioner is not needed for this mod because the K24 one will suffice. That is why I will be saving this tensioner. That's a good 60 dollars in my pocket :)

Here's the removed oil pump chain tensioner with its bolts. I later put this in a bag with its bolts to make sure I didn't lose it.

Next I took an allen key and a cheater bar (a large copper pipe, lolz) and removed the K24 oil pump chain guide. Supposedly this guide is too long to work with the K20A2 oil pump chain and oil pump assembly. To fix this, an RSX Type-S oil pump guide will be needed. Its part number is listed above.

Here is a pic of the tensioner on the left with its three hex bolts and the guide on the right with its two oddly shaped allen bolts:

I can't remember, but I believe there are four bolts holding the K24A1 oil pump onto the bottom end of this motor. Proceed to remove the pump after you have removed all of the stuff holding it on...like the tensioner, guide, chain, sprocket, etc.

Looking at the pump, you can see the balance shafts. They're just counter-weighted shafts that spin with the pump to offset vibrations. Supposedly they're better for daily drivers, but honestly, most people don't think they make a huge difference. So this is another reason why I care not for the K24 oil pump.

;)

Thanks for reading guys. Until next time, you will just have to wait and see what the condition of the rest of this motor is in!

Peace.