Engine Builds for Dummies! Part 6

___________________

___________________

Whenever you take an engine apart to repair it by replacing parts or to rebuild it, it is wise in most cases to blueprint certain components of the engine, or to blueprint the whole engine in some cases.

Blueprinting is the process of getting measurements of engine components to determine whether they are within OEM spec, are out-of-spec but replaceable, or to determine if the components are completely shot.

To do this you'll need to buy some tools. I'll walk you through the tools that I bought first and tell you what they will be used for briefly, then I will show you how to use them in the pictures of my blueprinting of the engine block.

One thing you will need to buy for blueprinting an engine is a set of feeler gauges. Mine are from Harbor Freight Tools. These allow you to measure clearances and to check your block for warpage. In addition these even allow for regular maintenance such as checking and adjusting valve lash.

Next, I purchased a dial bore gauge. It comes with a dial indicator that can measure travel to the nearest 0.0005". This dial bore gauge can measure the inner diameter of a bore, such as a cylinder in a block.

Because the hand is not the most accurate tool to hold precision instruments like a travel gauge, you'll want a magnetic base. This can hold the gauge to measure the run-out of brake rotors or of the crankshaft mains, particularly, for this engine build.

This tool that I'm about to show you I've had for quite a while. It's a Mitutoyo digital caliper. This can be used for measurements of thicknesses and stuff and even depth. I used it to find the point in the cylinder where I would need to measure from the top and bottom for out-of-round.

This is a precision straight edge. It is used to measure straightness-- like of a block's deck or of a cylinder head's bottom surface. This tells us whether our part is warped or not.

Lastly, this beautiful set of micrometers belongs to the wonderful maintenance manager at my chemical plant. This cool guy gave me a tool which could be used to measure crankshaft main diameters, crankshaft main out-of-round, and to calibrate the dial bore gauge.

With the engine up on the engine stand, the first measurement I decided to take was the run-out of all of the crankshaft mains. However, I forgot to account for the fact that magnets don't stick to aluminum and therefore I screwed myself over...only being able to blueprint the run-out of one main journal.

So to fix this problem I moved the block to the floor where the block would be nice and steady and mounted the magnetic base somewhere solid as well to begin measuring the run-out of ALL journals.

But even mounting the magnetic base somewhere solid didn't work because the setup was too bulky to fit in between the counter-weights. So I ended up taking oil pan bolts and threading them into the block and then fitting the gauge in between the bolts and the crank. This would allow me to keep the crank rotating a full 360 degrees while not hitting the gauge. All I had to do was be sure to keep everything as stable as possible as to not mess up any of the readings.

Per the Acura TSX Service Manual, the maximum allowable run-out specifications are:

- Standard (New): 0.03 mm (0.0012 in.) Max.

- Service Limit: 0.04 mm (0.0016 in.)

And per my sweet travel indicator, the max run-out I ever saw on any of the main journals was 0.0005 inches, much less than the standard allowable run-out.

Next I pulled the crank out and did a quick visual inspection of the webs on the block and I really freaked myself out.

I saw all of these little cracks around the bosses for where the oil squirters would be placed had this block been out of a TSX and not a CR-V.

Initially I thought that the block was cracked and that my build was done, but the good people of K20a.org informed me otherwise. These are casting marks. They are normal in this place and on this motor, so I felt much better after learning this.

If the block were cracked then I would have been in a bad position. I would have had to scrap it, and possibly restart the whole build with a new block...

And with all of the work I put forth into this already...I would have been kind of devastated. Crazy right? Phew.

This is also a good tool-- a piece of paper:

Diameter in the x and y direction would be measured on each of the journals and recorded on this piece of paper. The difference between these measurements will give journal out-of-round.

Also, I was going to measure the taper of each journal but I decided against it. However for the sake of the reader I have included out-of-round specs and the taper specs included in the factory service manual.

Journal Out-of-Round:

- Standard (New): 0.005 mm (0.0002 in.) Max.

- Service Limit: 0.010 mm (0.0004 in.)

Journal Taper:

- Standard (New): 0.005 mm (0.0002 in.) Max.

- Service Limit: 0.010 mm (0.0004 in.)

You'll want to first calibrate the micrometer you're going to use to measure the diameter of the journals. You have to use a 1-2" micrometer to measure the journals on the crank but this short tutorial is just for the calibration of a micrometer.

For any vernier micrometer you'll be able to measure from x inches to x+1 inches. In other words, one micrometer will measure 1-2", another 2-3", another 3-4" and etc.

The micrometers will come with reference points, usually metal sticks or dowels which are machined with a certain certainty to a given length. One of the dowels is shown next to a micrometer in the following picture:

Take the dowel and place it in between the jaw of the micrometer. Tighten the micrometer onto the dowel using the ratcheting mechanism on the end of the tool.

Read the vernier micrometer and write down your measurement of the first dowel. If you don't know how to read a vernier micrometer, I suggest you look at this video for help:

Write down the value of your measurement and the size of the dowel you measured. Then, repeat this step for the second dowel that can fit in your micrometer.

These two values each have an offset due to an error present in the tool. What that means is that although the dowels are precision machined to their own respective lengths, the tool may read a little bit off.

So while in theory the dowels are machined to maybe 3.000" or 4.000" (depending on how precisely they were machined) the tool may read 3.005" or 4.001". And in order to accurately blueprint your engine you need to account for this. Let's make a table and look at the values. It might make you think a bit...and thinking is ALWAYS good!

Notice how the offset decreases with the longer dowel. Let's assume that this is a trend, and not just due to noise. If there were dowels in between three and four inches in length, then we would know for sure whether the offset randomly varied per measurement. However for now, we must assume that the offset decreases as the dowel size increases.

Given that this is a known phenomenon, drift, as it is called, I decided to assume the aforementioned trend was accurate. And assuming the trend is accurate, you can predict how much offset you will get for measurements in between three and four inches using the formula shown at the right in the above picture.

Of course, this technique can be applied to more micrometers than just the three to four inch one. It can be applied to any outer measurement micrometer. Now, if I want to measure a diameter that is, let's say 3.25 inches, then I know that whatever reading my tool gives, it will have an offset of approximately 0.004 inches.

Y = 0.004*X + 0.017

Y = 0.004*(3.25 inches) + 0.017

Y = the offset we are looking for at a measurement of 3.25 inches = +0.004.

So, you get a reading of 3.25", but you know that at this measurement, the offset is +0.004. This means that your measurement is actually 0.004 inches too high. The actual diameter of our theoretical object is 3.21 inches.

If you're still confused about this don't sweat it. As I mentioned it is just an approximation so the likelihood that it is totally accurate is not 100% anyway. If you are still interested however, just leave me a comment and I'll answer your question.

After calibrating the micrometer, I began to measure the diameter of the crankshaft journals. Twice in the x direction and twice in the y direction. Then I calculated out-of-round and entered it into an Excel Sheet. I measured twice to be sure my measurements were exact.

Let's look at the values shall we?

It seems as though, even though some of the measurements weren't repeatable-- probably due to my inexperience-- that the journals were not significantly out-of-round. If they were, then within the service limit the journals would have to be redone. The crank would need to be turned and polished. However this is not necessary.

The next thing to do is to measure the cylinder bores of the engine block. In the Acura TSX Service Manual there are three different heights within the cylinder suggested to measure at...one at the top, one at the middle, and one at the bottom.

Taking your caliper with depth measurement, measure 0.2 inches from the bottom of the cylinder and mark that point with a marker.

Then measure 0.2 inches from the top of the cylinder and mark that point.

Measure the distance between the two marks with your caliper and mark the middle point. These are the three depths that you need to measure diameter of the cylinder bore at in the x and y direction.

Here's how the dial bore gauge looks assembled...look at the circled part:

The circled part is the part that goes into the cylinder bore. The first part of calibrating the gauge is knowing how long this part needs to be. And since it is assembled, it is up to you, the blueprint master, to assemble it properly.

You'll notice that there are four letters on the corner of the deck of the block ("AAAA"):

These letters are each representative of each cylinder bore size and there are two possible letters which may be inscribed on the deck-- A or B. You will be using these cylinder bore sizes to figure out how long the measuring part of the bore gauge must be. Check it out:

- Cylinder Bore Size Standard (New):

- A or I: 87.010-87.020 mm (3.4256-3.4260 in.)

- B or II: 87.000-87.010 mm (3.4252-3.4256 in.)

- Service Limit: 87.070 mm (3.4279 in.)

- Oversize: 0.25: 87.250-87.260 mm (3.4350-3.4354 in.)

- Reboring Limit: 0.25 mm (0.01 in.) Max.

- Bore Taper Limit (Difference between first and third measurement): 0.05 mm (0.002 in.)

So, the measuring part must be long enough that when it enters the bore it can compress and give a reading on the gauge, but not so long that it doesn't fit in the bore. To satisfy those conditions I chose 3.4" metal piece:

And I installed a 0.04" washer. This gives me a total length of 3.44" for the sensing part of the gauge.

Then I took my micrometer and I opened it to the size of my cylinder bore while accounting for offset (which I talked about earlier) to be as accurate as possible. I locked the micrometer, and then I clamped it with a soft clamp to a table being sure not to damage either the table or the micrometer.

Regardless though I will need to bore out these cylinders to 87.5 to 88 mm on stock sleeves because they are worn past OEM spec. If they weren't, cast pistons would be an option, but ordering .25 mm oversized TSX pistons and rods brand new would be nearly as expensive or more expensive than some forged options.

Then, with the micrometer opened to the known cylinder bore diameter according to my block's deck, I inserted the assembled dial bore gauge and I rocked it back and forth in between the micrometer's jaw.

While rocking the dial bore gauge back and forth, the sensing element becomes compressed and uncompressed and this makes the gauge on the travel indicator move back and forth. At the point where the gauge reaches a stop, that is it moves up, stops, then moves back down, you have your reference point.

This point of measurement is the size of your cylinder bore, and if the cylinder bores are not warped or changed at all from operation then your dial bore gauge should consistently give out this reading.

Take the face of the dial, and rotate it so that the 0 mark lies at this point:

If you're still confused. Check out this video, or leave me a comment and I'll get back to you. This stuff is tricky and it may not come easily the first couple of times you look at it:

Now we're going to begin measuring the diameter of the cylinder bore at three different depths in the x and y direction. Insert your gauge into the bore and rock it back and forth until the gauge reaches its stopping point, similar to how you calibrated the gauge:

Turn the gauge in the y direction, and repeat this step at each of the three depths.

To get started on looking at the results, I made up a little diagram.

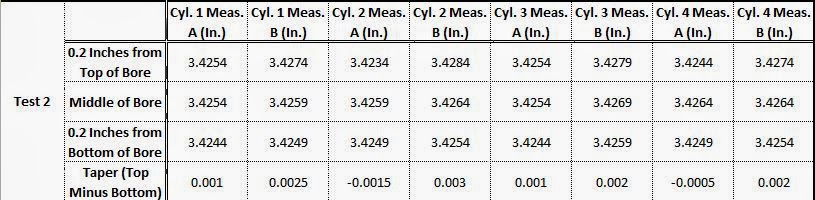

I then measured the cylinder bores and recorded the measurements in Excel. Once for each test:

One thing that I did notice was that the cylinders were worn past OEM spec in the direction of the con-rod force. This is apparently normal according to the thread I made on K20a because the con-rods elongate the cylinder bores.

Lastly we're going to see if the deck of the block is warped. This step in the process is very simple. It's not too taxing and it's not too technical. You take a big ruler, basically, and you lay it on the top of the block. If the block's deck isn't warped-- that is it is completely straight, then the ruler will have no spaces in between it and the surface of the block, right?

And if it wasn't straight, then you would have spaces in between the ruler and the block. Well, this is where our feeler gauges come in. By measuring the spaces in between the precision straight edge and the block it is possible to determine how warped the block is, if at all.

You will want to perform this process in multiple directions across the deck of the block.

If the block is warped, then the spaces in between the precision straight edge and the block will be greater than these values:

Engine Block Warpage:

- Standard (New): 0.07 mm (0.003 in.) Max.

- Service Limit: 0.10 mm (0.004 in.)

Let's look at some pics, shall we? You'll notice that I even measured length-wise. This is just to get a little more insight into the shape of the block.

Here are the measurements I took:

And here are the promising results showing that the block is not warped and that all clearances are within OEM spec:

In conclusion the block is mainly in good shape and so is the crankshaft. The only worries I have are about the cylinder bores. Because they are out-of round, I will need to have them bored and honed out to 87.5 mm or 88 mm which are the safest bore sizes on stock sleeves.

Then I plan on running 4032 alloy forged pistons so that I can run tighter piston-to-wall clearances rather than 2618 alloy forged pistons.

Although the 2618 alloy pistons are stronger, they are more ductile and they expand more when exposed to heat. So the piston to wall clearances must be increased.

You can read up more on those choices here.

Anyway, for now I'm out. It's been a long-winded and tiring article but I HOPE it offered you a lot of information and made you appreciate the art of blueprinting more. Until next time, keep it chill.

Anyway, for now I'm out. It's been a long-winded and tiring article but I HOPE it offered you a lot of information and made you appreciate the art of blueprinting more. Until next time, keep it chill.

No comments:

Post a Comment

Comment