Hello ɭexi.ɭaron viewers!

Today's addition is a little late, and I apologize for that, but for the tuners out there, I have a story that will stress the linear relation between chassis rigidity and handling.

Before I go any further, think back to the Swindon Honda Plant post that I made about a week ago. In the second part of the plant tour video, you get a peek at how engines, suspension, steering racks, and all are assembled to the chassis all at once.

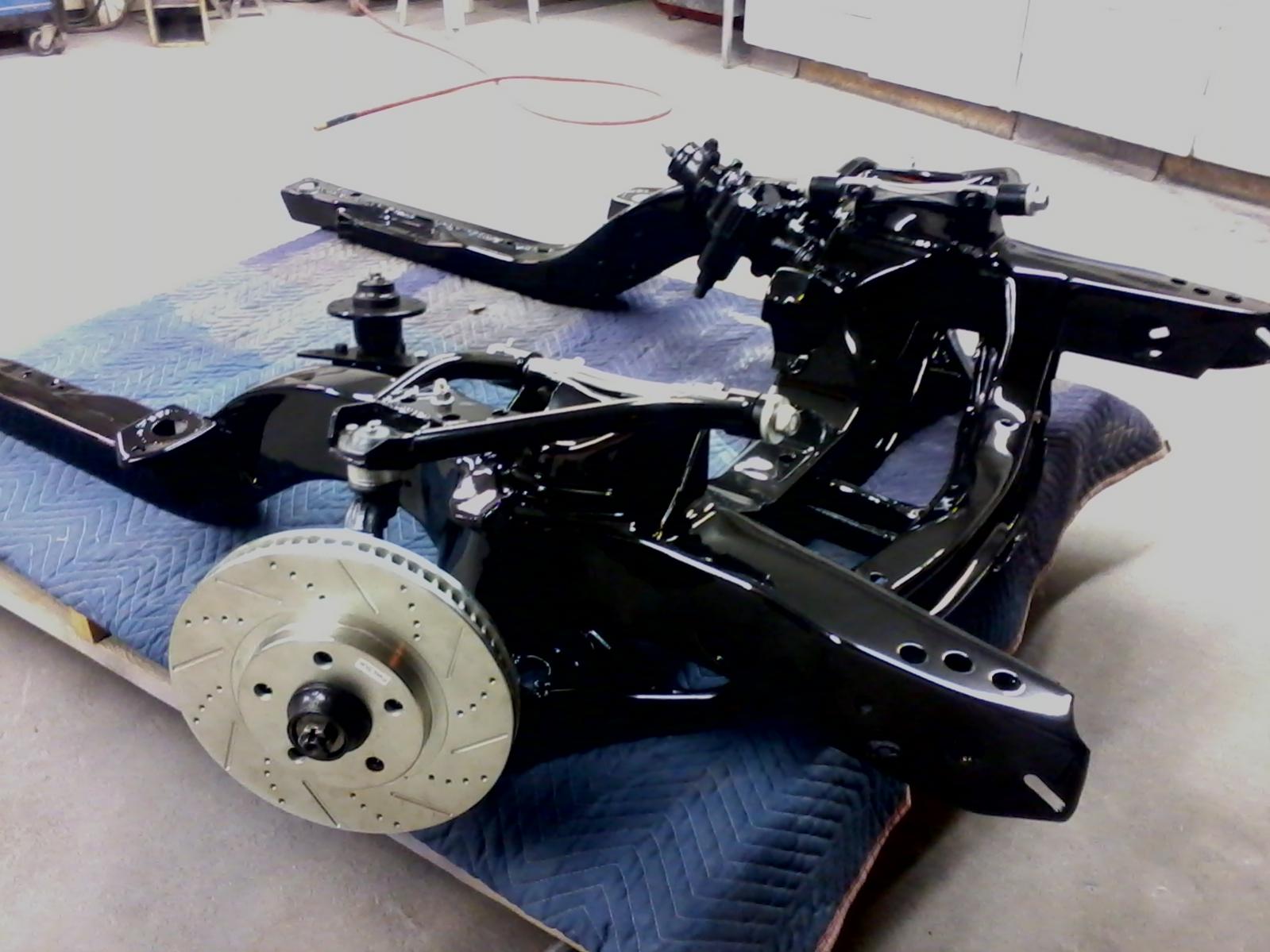

Well, this is a subframe assembly.

All of the aforementioned components are mounted to it, and it is jacked up and attached to the bottom of the car's chassis. When the two are mated, chassis and subframe, there are significant gaps between the threads of the bolt and the threads of the subframe assembly's hole. Also, there are slight imperfections in between the subframe assembly's and chassis's hard metal which make it hard for the fit and finish to be perfect. Check out this illustration.

By placing a piece of special alloy in between the bolt and the subframe and chassis, it is possible to eliminate motion which occurs even when the bolt is torqued.

This eliminates much of the vertical motion experienced when going over bumps in the road, thus eliminating bump-steer, improving stability and response at all speeds, and lowering road noise. Check out this video.

Today's addition is a little late, and I apologize for that, but for the tuners out there, I have a story that will stress the linear relation between chassis rigidity and handling.

Before I go any further, think back to the Swindon Honda Plant post that I made about a week ago. In the second part of the plant tour video, you get a peek at how engines, suspension, steering racks, and all are assembled to the chassis all at once.

Well, this is a subframe assembly.

All of the aforementioned components are mounted to it, and it is jacked up and attached to the bottom of the car's chassis. When the two are mated, chassis and subframe, there are significant gaps between the threads of the bolt and the threads of the subframe assembly's hole. Also, there are slight imperfections in between the subframe assembly's and chassis's hard metal which make it hard for the fit and finish to be perfect. Check out this illustration.

By placing a piece of special alloy in between the bolt and the subframe and chassis, it is possible to eliminate motion which occurs even when the bolt is torqued.

This eliminates much of the vertical motion experienced when going over bumps in the road, thus eliminating bump-steer, improving stability and response at all speeds, and lowering road noise. Check out this video.

No comments:

Post a Comment

Comment